Type G

Used in the UK, Ireland, Saudi Arabia, Hong Kong, and the UAE.

Type F

Used in the EU (except Ireland), Korea, Russia, Egypt, and mainland China.

Type B

Used in the USA, Canada, Japan, Taiwan, Mexico, and mainland China.

Type I

Used in Australia, New Zealand, and mainland China.

Country not listed? We ship worldwide. Please contact us if you are not sure which plug type you need.

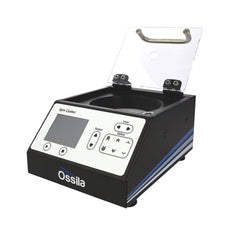

The Low Price, Vacuum-Free Spin Coater You Can Trust

Produce high-quality films without any substrate warping

Overview | Specifications | Features | Gallery | In the Box | Accessories | Resources and Support

The vacuum-free Ossila Spin Coater is the ideal spin coating machine for busy, fast-paced labs where space is at a premium. The system is both robust and affordable, allowing everyone to implement spin coating in their research. With free worldwide shipping as standard and our two-year warranty included at no extra cost, the Ossila Spin Coater is trusted by academics and researchers around the world.

Designed to dramatically improve the quality of thin film which can be achieved with spin coating, while also eliminating the service requirements necessary with vacuum pumps and nitrogen lines, the Ossila Spin Coater is able to produce uniform coatings with zero substrate warping. The reduced need for servicing keeps running costs to a minimum and the straight-forward operation of the device makes spin coating quick and easy, without compromising on functionality.

As it comes pre-loaded with onboard control software and does not require a vacuum pump or nitrogen line, the Ossila Spin Coater is a true plug-and-play device. Combined with its compact size, not only does it take up very little space on the bench compared to other spin coaters, but it can also be used in a glove box with ease should an inert atmosphere be required.

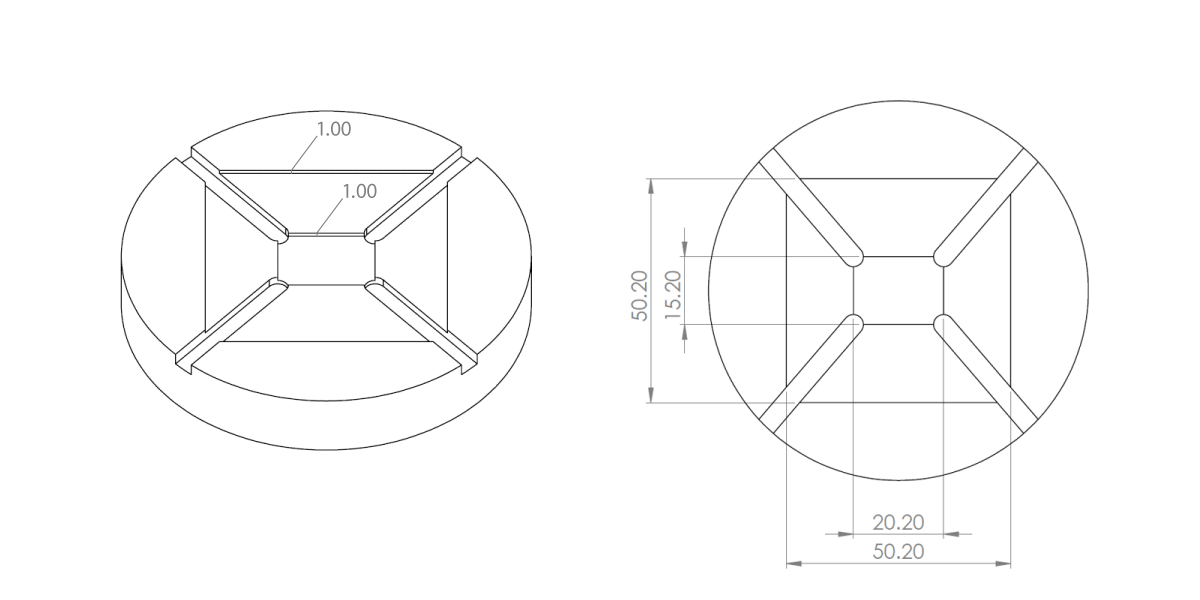

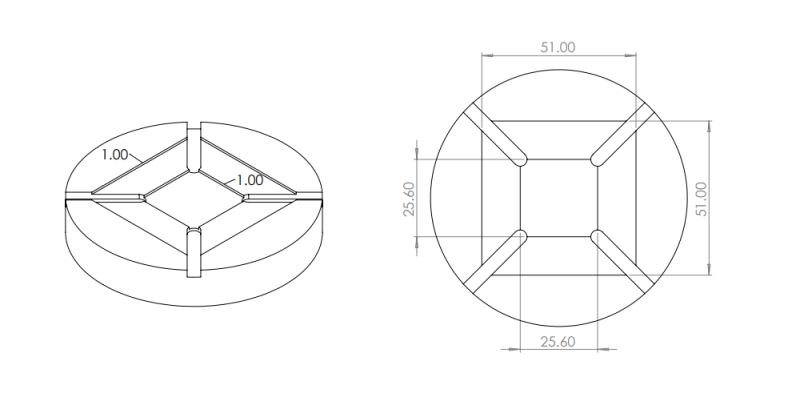

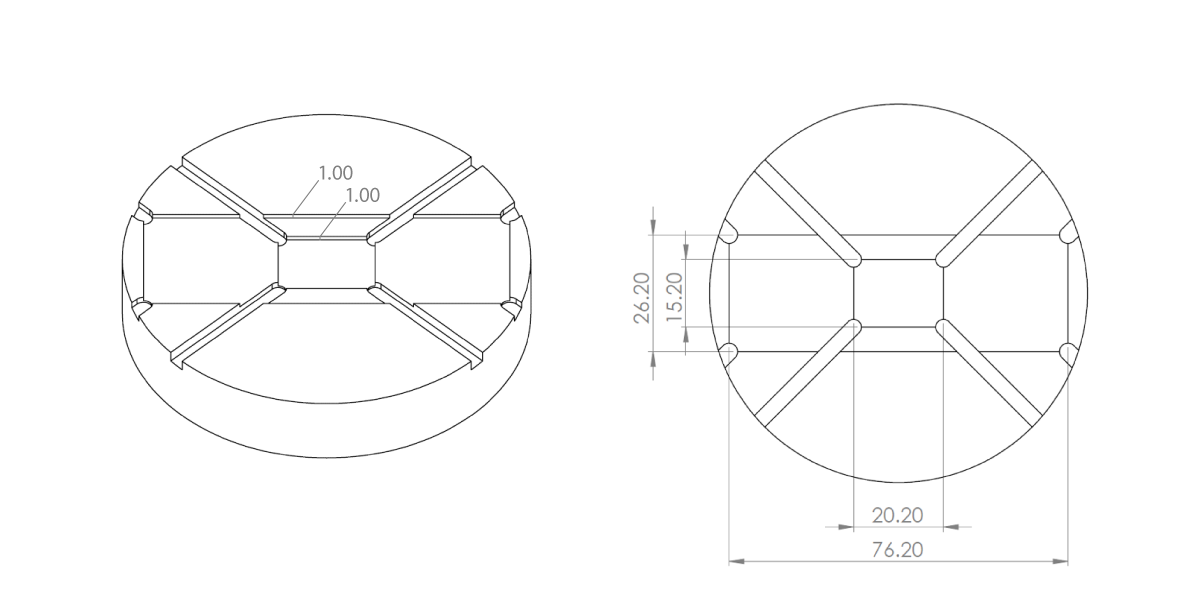

The spin coater comes with one FREE spin coater chuck. Please select which you would like when placing your order. If you want a custom-milled chuck to fit your own substrate system, please contact us (specifying the length, width, and depth of your substrate) to discuss options. Custom Spin Coater Chucks can be ordered to fit substrates of any shape and additional chucks are always available.

For controllable, automated dispensing of solvents, the Ossila Spin Coater is also available with either our single syringe pump or dual syringe pump at a discounted price as part of the Ossila Spin Coating Kit.

Two-Year Warranty

Buy with confidence

Lab Ready

Resilient and durable

Easy to Use

User friendly design

Low Maintenance

Easy to keep running

Space-Saving Design

22.5 cm x 17 cm footprint

Range of Speeds

120 to 6000 rpm

Vacuum Free

Innovative chuck design

Great Value

Affordable and high quality

Specifications

| User Profiles | 10 |

|---|---|

| Programs | 10 programs on each user profile, with up to 50 steps each |

| Speed stability | <2% error |

| Speed | 120 to 6000 RPM |

| Spin time | 1 – 1000 sec |

| Power supply | DC 24 V 2 A, via 100–240 V 50/60 Hz power adapter |

| Safety Switch | Magnetic safety switch on the door |

| Dimensions (D x W x H) | 225 mm x 170 mm x 140 mm (8.86" x 6.69" x 5.51") |

| Weight | 2.9 kg |

| Materials | Polypropylene bowl, steel casing, tempered glass lid |

Spin Coater Features

Large Range of Speeds

Spin speeds range from 120 to 6000 rpm, covering a range of different spin coating conditions — from slow dry crystallisation, to ultra-thin films.

Easy to Install

With no vacuum or nitrogen line to connect, simply plug the spin coater into a power socket to get started on your research.

Full Control

The inbuilt control system allows you to have a maximum of 10 separate user profiles — with each profile capable of saving 10 recipes with up to 50 steps. All this makes our spin coater perfect for anyone that has to share equipment in a busy lab.

Fewer Variables, Better Films

The inbuilt spirit level and adjustable feet ensure a flat spinning axis, and the vacuum-free chuck prevents warping in thin substrates. Both factors lead to better uniformity in films — and better device performance.

Safety First

The spin coater is powered by a 24 V DC power supply, so no high voltage or specialist power with additional requirements is needed. Shielded from solvents and tampering, there is a magnetic safety switch that stops the chuck from spinning when the lid is open.

Why Go Vacuum-Free?

Many spin coaters in the market use vacuum pumps to hold substrates while they spin. The Ossila Spin Coater uses an innovative chuck design that does not require a vacuum. Substrates are held in place by recesses cut into a polypropylene chuck, allowing excess coating material to be drained away.

Thin substrates are likely to be warped inwards by vacuum chucks, affecting coating uniformity. The force of vacuum on the solutions deposited on top of porous substrates, such as ceramics, also leads to inhomogeneity. This reduces the quality and performance of devices. Our vacuum-free chucks ensure an even film distribution by keeping your substrates flat and free from damage, even if they are flexible substrates.

Without a vacuum line, the Ossila Spin Coater can be set up anywhere with a single mains socket. Spin coat on a lab bench, in a fume hood, or a glove box, all in the same day thanks to its easy setup and compact size.

Most spin coaters are also burdened by the hidden cost of vacuum pumps that are usually excluded from the full system price. Vacuum pumps are prone to breaking, resulting in expensive repairs and delays. This is mainly caused by excess solvents being sucked into the vacuum line, damaging the internal components. Short-term and long-term costs can be reduced by using the vacuum-free Ossila Spin Coater, which gives you everything you need to start spin coating.

Spin Coater Gallery

Ossila Spin Coater Testimonials

We recently purchased an Ossila Spin Coater. Its compact size and vacuum-free system is ideal for our rather over-crowded laboratory, and it has enabled us to prepare a series of high-quality block copolymer thin films. The chucks make it easy to use different substrates and we have programmed several spin cycles, which allows systematic variation of the copolymer film thickness with good reproducibility.

Professor Steve Armes FRS, Professor of Polymer and Colloid Chemistry, University of Sheffield

I use a Contact Angle Goniometer and Spin Coater from Ossila, the best tools I have ever used for the application of Perovskite solar cells. I plan to order more devices from the same brand.

Ashique Kotta, Jeonbuk National University

In the Box

- Spin coater

- Spin coater chuck

- Power supply

Accessories and Related Products

Spin Coating Kit

- Even Higher Quality Coatings

- Unbeatable Value

- Free Connector

Available From £3900